As battery manufacturing evolves, the testing of them has become ever more critical. The use of Test Probes plays a pivotal role in delivering accurate and repeatable results. This testing includes all different types of batteries, including battery cells and Li-ion energy storages. Whether you're manufacturing battery cells or electric vehicles, consumer electronics or grid storage systems, Peak Test delivers high performance probes that are engineered to deliver consistent results.

Why High Current Battery Testing matters

High Current Test for batteries must replicate real-world load conditions, uncovering potential failure points during production. This form of testing is particularly useful in testing Li-ion batteries, pouch cells, prism cells and cylindrical cells.

High Current Testing helps to:

- Identify internal resistance issues

- Detect manufacturing defects early

- Evaluate how batteries respond under heavy load or rapid discharge

- Measure voltage drops

- Predict battery degradation over time

This type of testing also plays a critical role in applications such as EV battery testing, where safety and performance are key. By simulating real world situations, manufacturers can meet industry regulations and customer expectations.

Role of Test Probes in High Current Testing

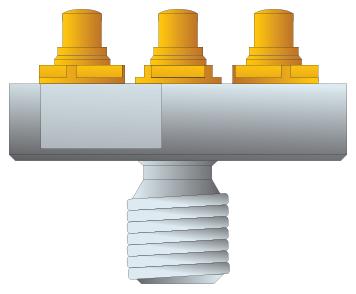

Using Test Probes provides a low resistance connection between the test system and the battery under test. Spring loaded plungers ensure robust contact, even across slightly uneven or inclined surfaces. This also includes surfaces that are oxidised or have been contaminated in some way, supplying you with an accurate connection every time.

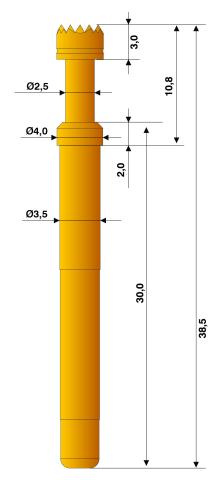

Probes, such as our HSP50 Series, are examples that always hold a high standard of testing. Probes such as this provide reliable contact under high current conditions. Designed specifically for Battery and High Current Testing, reliable and low-resistance contact is delivered every time. Their spring-loaded mechanism preserves firm connection, even with slight surface irregularities. As a result, test accuracy and consistency improve through repeated use.

Scratch Technology and Reliable Testing

Maintaining a low contact resistance is crucial in High Current Testing, even small measures of contact resistance can generate heat or cause an error in measurement. This introduces the innovation of scratch technology, which uses defined scratch movement on the contacted surface. Scratch contacting is also beneficial when testing contaminated or oxidised surfaces, lightly abrading the surface to get a reliable contact.

The typical aluminium current collector on Battery Cells can be reliably contacted this way, making this technology suitable for use across several battery types. This also avoids the occurrence of a "wetting current" effect, which is critical when surface cleanliness can vary. While a wetting current can be generally beneficial, as it can break through any surface films, it can also be detrimental to the health of the battery by causing issues like contact failure.

Integrated Temperature Sensors and Voltage Sense Pins

Some High Current Probes often feature Spring-Loaded Temperature Sensors, enabling Kelvin measurement directly at the point of contact. This delivers highly accurate, low-resistance readings and thermal monitoring during High Current Testing all within the same array. These probes sport a slim design, meaning they can be integrated into various contacting units, such as Co-axial High Current Probe with an internal pin. Sense pins are often configured into these probes to ensure accurate voltage testing under high currents.

Effective High Current Battery Testing demands a careful selection of probe technology. Key attributes include: low contact resistance, scratch contacting, high current capability and integrated voltage/temperature sensing. By using Peak Test’s High Current Probe Series, you can conduct reliable and repeatable testing across a large variety of battery cell types. With the industry’s shift toward EV and energy storage systems, High Current Probe solutions remain a cornerstone for quality and performance.