High charging currents, evolving standards, and safety requirements mean that High Current Probes for EV Testing must deliver exceptional accuracy and reliability. Whether for production-line quality control or research and development, these test probes are essential tools for validating EV Charging systems.

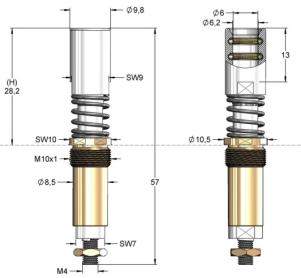

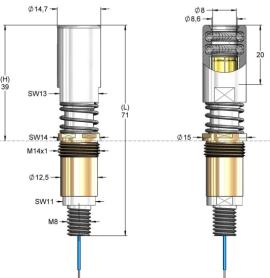

Round pins or round sockets are built into all new charging plugs for electric mobility all over the world. Therefore, we offer solutions for common diameters (Ø4.0 / Ø6.0 / Ø8.0 / Ø10.0 mm). Other sizes are available on request.

The contacting of round pins is of great importance for e-mobility applications.

Why EV Connector Testing requires High Current Probes

This form of testing relies on robust connector systems that are capable of safely transmitting high power (often over 100 A) through contact pins. These pins must maintain low resistance, high conductivity, and mechanical durability under repeated use.

Key challenges in EV Testing include:

- Heat generation due to contact resistance

- Mechanical stress on charging pins

- Ensuring reliable charging under real-world conditions

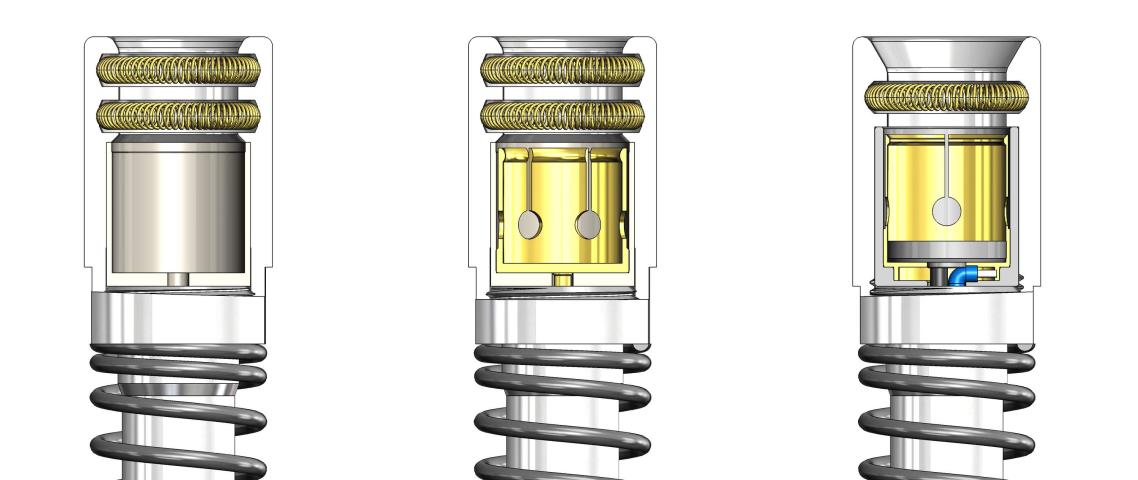

E-mobility with fast charging processes at high currents also poses completely new challenges for contacting and testing technology. Reliable contacting with minimal contact resistance and high current carrying capacity is required for testing corresponding components and interfaces. Intelligent contacting solutions also enable the detection of mechanical details, the presence of protective devices or the monitoring of temperature characteristics.

Optimised Probe Design for EV Test Applications

High Current Probes must strike a balance between electrical performance and mechanical reliability.

Key design features include:

- Spring-loaded plungers: For low resistance, repeatable contact.

- Threaded test heads: For secure grounding in test blocks.

This range of probes have been specially developed for typical round pin contacting. The special probe design with a ring spring allows reliable and damage-free contacting of the DUT at currents up to 200 A and is ideally suited for handling different tolerances of round pins.

A prime example is the HSP111/G series, which supports up to 100 A and a continuity resistance of 6.00 mOhms.

Applications of High Current Probes in EV Testing

High Current Probe application spans across a variety of areas.

Uses include:

- Battery Testing: High Current Probes are crucial for evaluating the charging and discharging of batteries.

- Power Supply Testing: They are used to assess the performance and efficiency of power supplies, ensuring that they can handle required current levels.

- Cable Harness Testing: They can verify the integrity and current-carrying capacity of cable harnesses that are used in various applications.

- Component Testing: High Current Probes are used to test the performance of individual components like resistors, diodes, and transistors under high current conditions.

Best Practices for EV Connector Testing

To ensure safe and accurate EV testing, it is advised to follow tried and tested procedures:

- Align probes precisely with connector pin centres

- Use flexible cables to reduce strain on tester heads

- Gradually increase current during testing

- Verify contact pressure and spring action before each test

Routine maintenance and careful alignment will help extend a probe's lifespan and will improve test repeatability.

Why High Current Probes are Critical for EV Testing

High Current Probes are essential for validating charging systems, they ensure low resistance contacts with connector pins, safe and high current simulation during testing, and long term connector performance and reliability.

Peak Test has a specialised range of High Current Probes, perfect for the EV Testing application. Our probes deliver the precision and durability needed for this form of testing.

Take a look at our range online.

Need help selecting the right probe?

Visit our Resources Page for Technical Guides and Datasheets, or contact our team of experts for guidance.