In the world of high frequency electronics, precision and performance are everything. Co-axial Spring Contact Probes are essential components in RF (Radio Frequency) testing, designed specifically to meet the demands of signal transmission across a wide frequency range. These probes offer minimal signal loss, high reliability, and are compatible with a wide range of RF connectors and devices under test (DUT). We can provide specialist contact solutions for various applications in RF Testing, covering a wide range of connections, including standard connectors and switch connectors.

What are Co-axial Spring Contact Probes

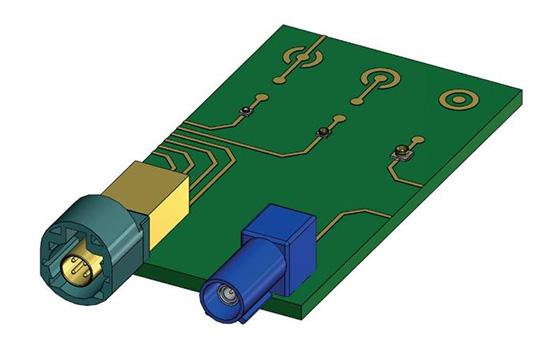

Co-axial Probes are a specialised type of Spring Contact Probe designed to be used across RF applications. Unlike standard probes, Co-axial Probes consist of inner and outer conductors configured to support efficient transmission of RF signals according to the signal requirements. Their dimensions and electrical parameters are precisely engineered to preserve signal integrity and minimise insertion loss over board frequency bands.

Thanks to this design, Co-axial Spring Probes are ideal for testing RF connectors, switch connectors, and RF test points on printed circuit boards (PCBs). They ensure reliable contact and repeatable test results, even in demanding environments.

Industry Applications

Our solutions cater to a wide variety of industries, including automotive and consumer electronics. These sectors often use standardised RF connectors such as SMA, SMB, SMC, and HSD used in automotive and consumer electronics, all of which can be accurately tested using our high performance contact solutions.

Whether you're validating a Fakra connector or testing high speed digital transmission, our probes deliver consistent and dependable performance.

Mounting Options

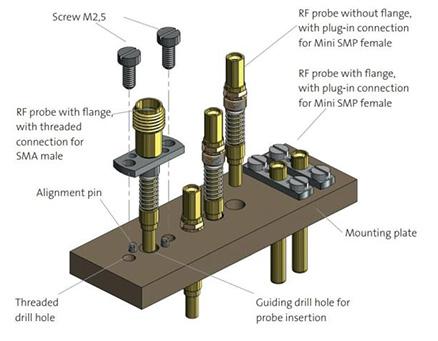

We understand that flexibility in mounting is key for seamless integration into various testing systems. That's why our P866x Series RF Probes come with multiple mounting options to suit different test setups:

Threaded Mounting

Some versions of the P866x Series can be directly threaded into the mounting plate. This method provides a stable and fixed mounting solution suitable for high-precision applications.

Flanged Mounting

Alternatively, other versions of the RF Probe are equipped with a flange that can be screwed onto the mounting plate. This flanged design allows for easy alignment and repositioning of the probe to accurately contact the DUT. However, proper mounting requires:

- Drill holes large enough to allow probe movement

- Threaded holes for fixing screws

- Guide holes and centering pins aligned with the flange's pattern

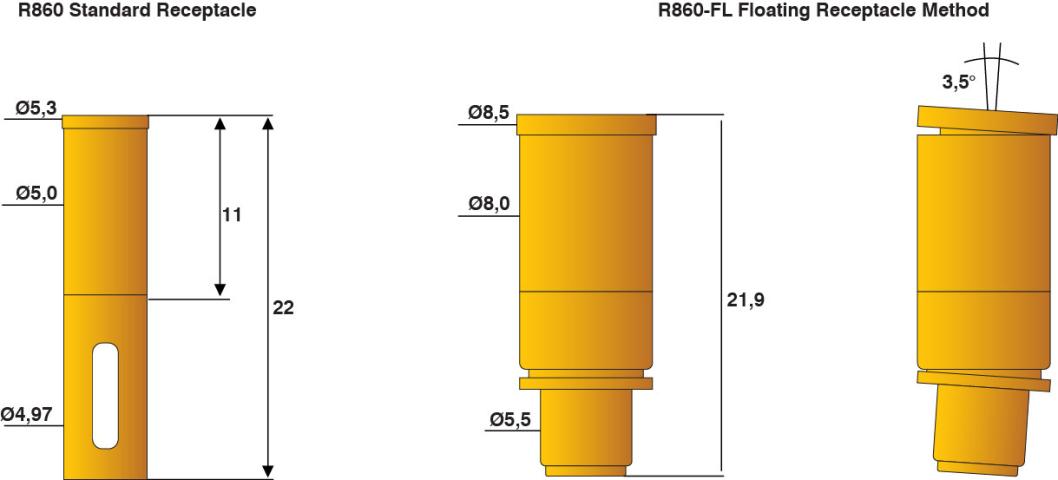

Floating Receptacle for Misalignment Compensation

In High Frequency Testing, even slight misalignments can lead to measurement errors or physical damage. To address this, we offer the R860-FL Floating Receptacle which is a unique mounting accessory compatible with the P860x series Co-axial Probes.

The R860-FL allows 360 degrees movement, enabling the probe to self align with the DUT. This design not only protects the DUT from potential damage but also ensures consistent signal transmission. Once the force is removed, the probe automatically returns to its' original position. This floating receptacle is only compatible with push fit Co-axial Probes.

Reliable RF Testing

Whether you're testing SMA, SMB, SMC, or HSD connectors, our range of RF Spring Contact Probes are engineered for accuracy, repeatability, and durability. With options like Threaded Mounting, Flanged Mounting, and Floating Receptacles, we offer the versatility needed to support today's high frequency test requirements.

If your application required precision testing or robust mounting solutions, get in touch with us today. Our team are ready to support you with solutions tailored to your needs.